Group Parter: Owaze Ansari

Master of Architecture in Emergent Technologies and Design

Architectural Association School of Architecture

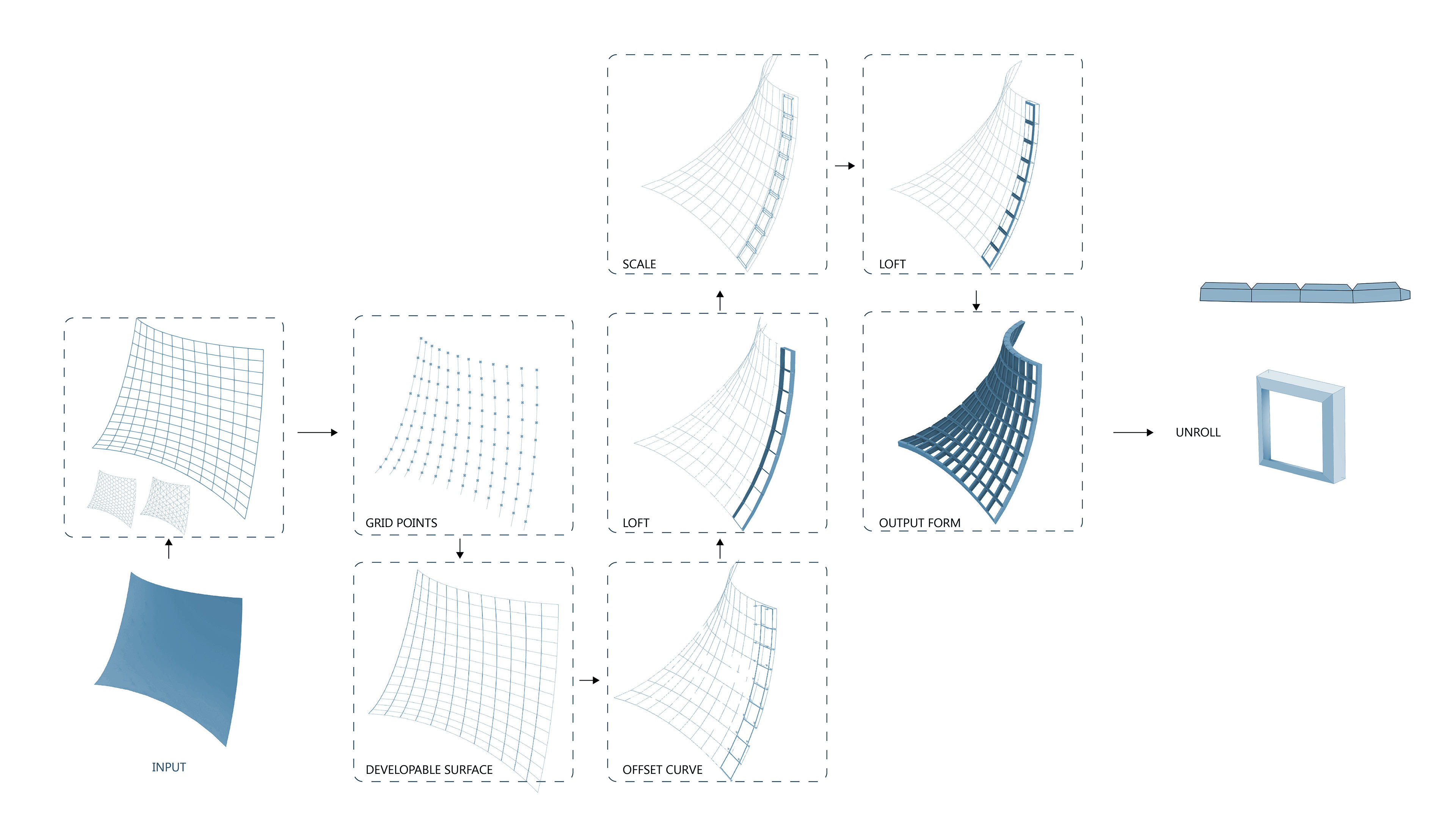

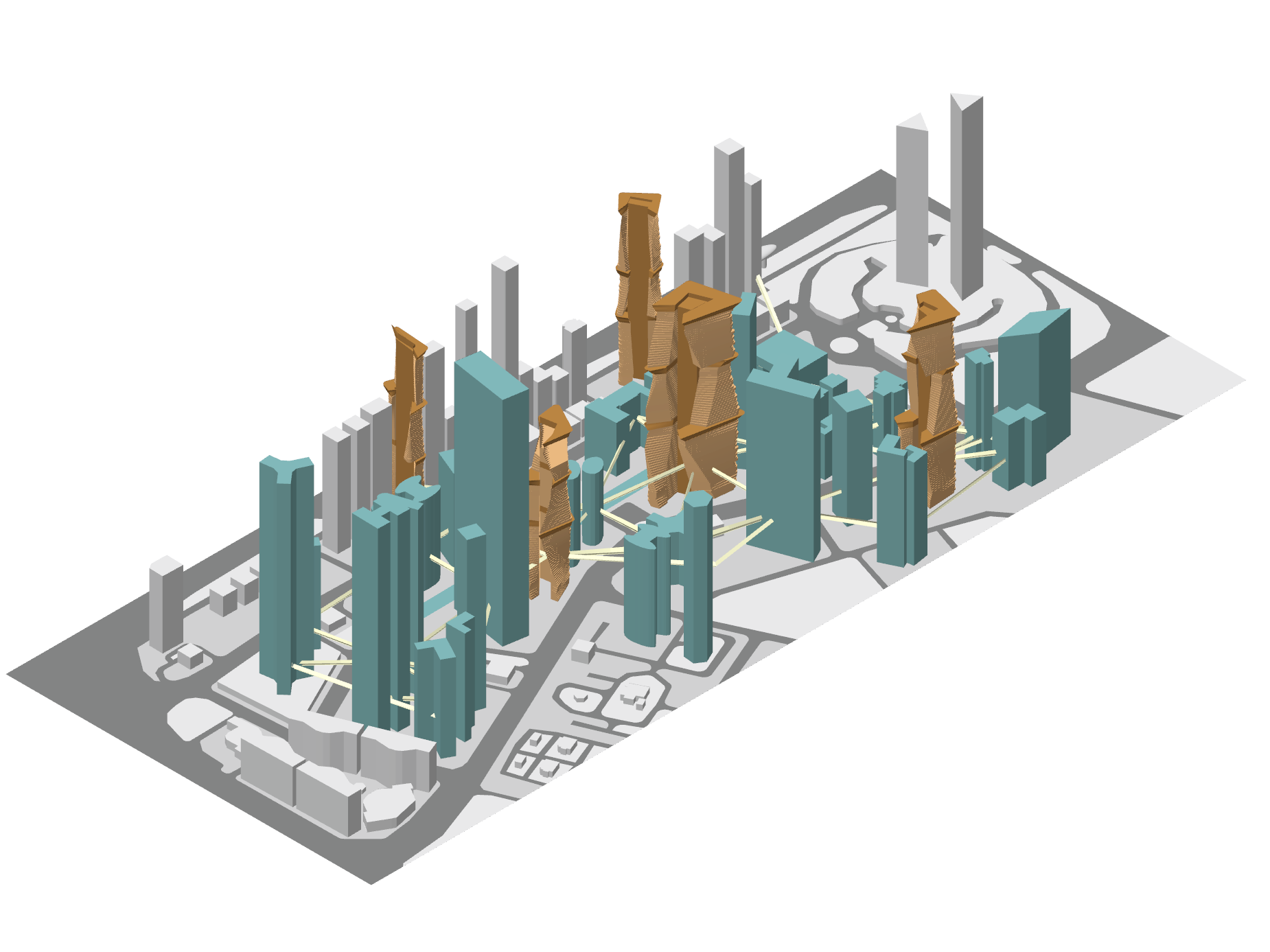

The following research was concentrated on the fabrication of a double curved diagrid surface. Our main intention was to understand the relationship along with its limitations between material behaviour and computational design. Further studies also included form generation, production and fabrication.

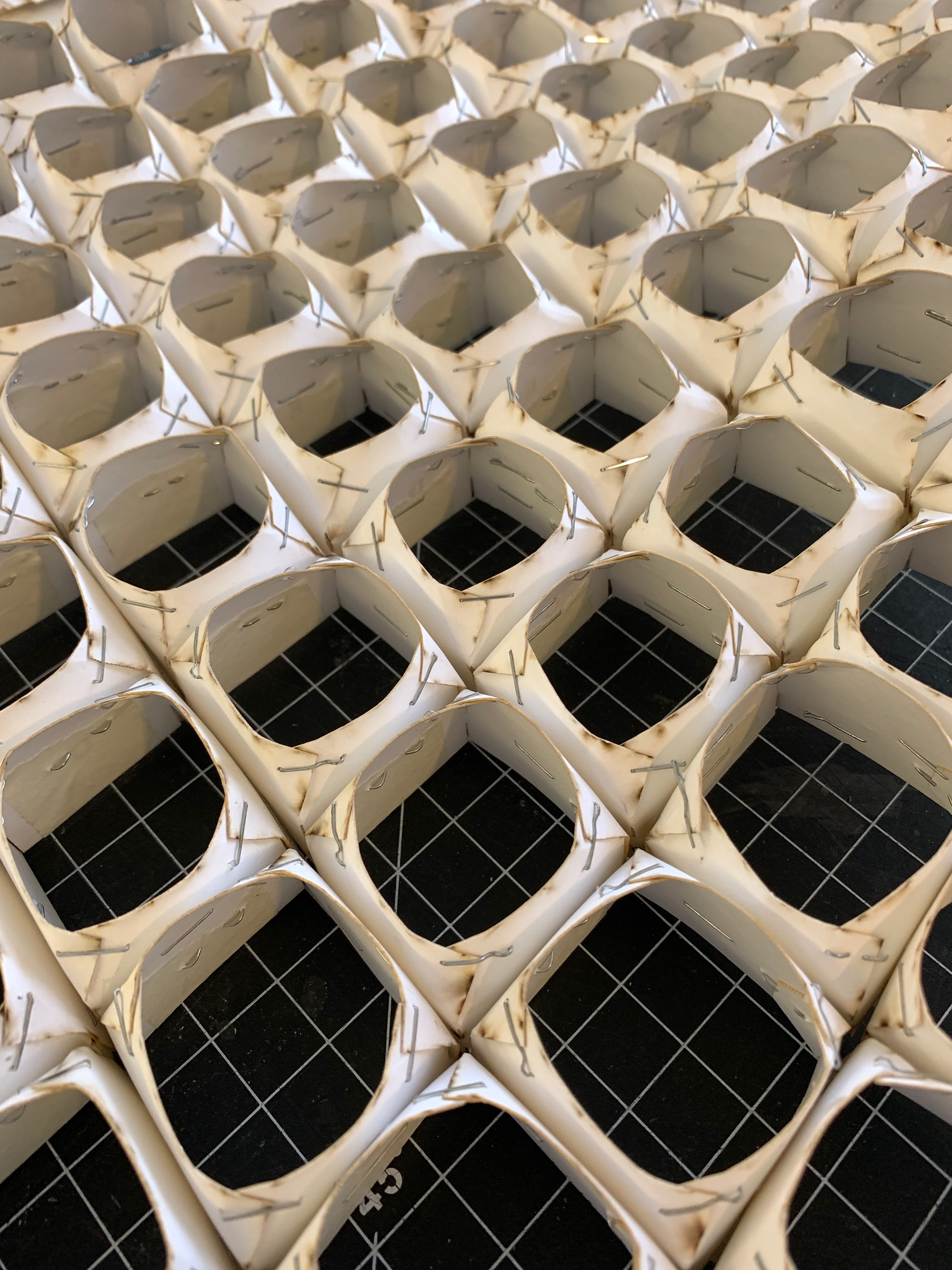

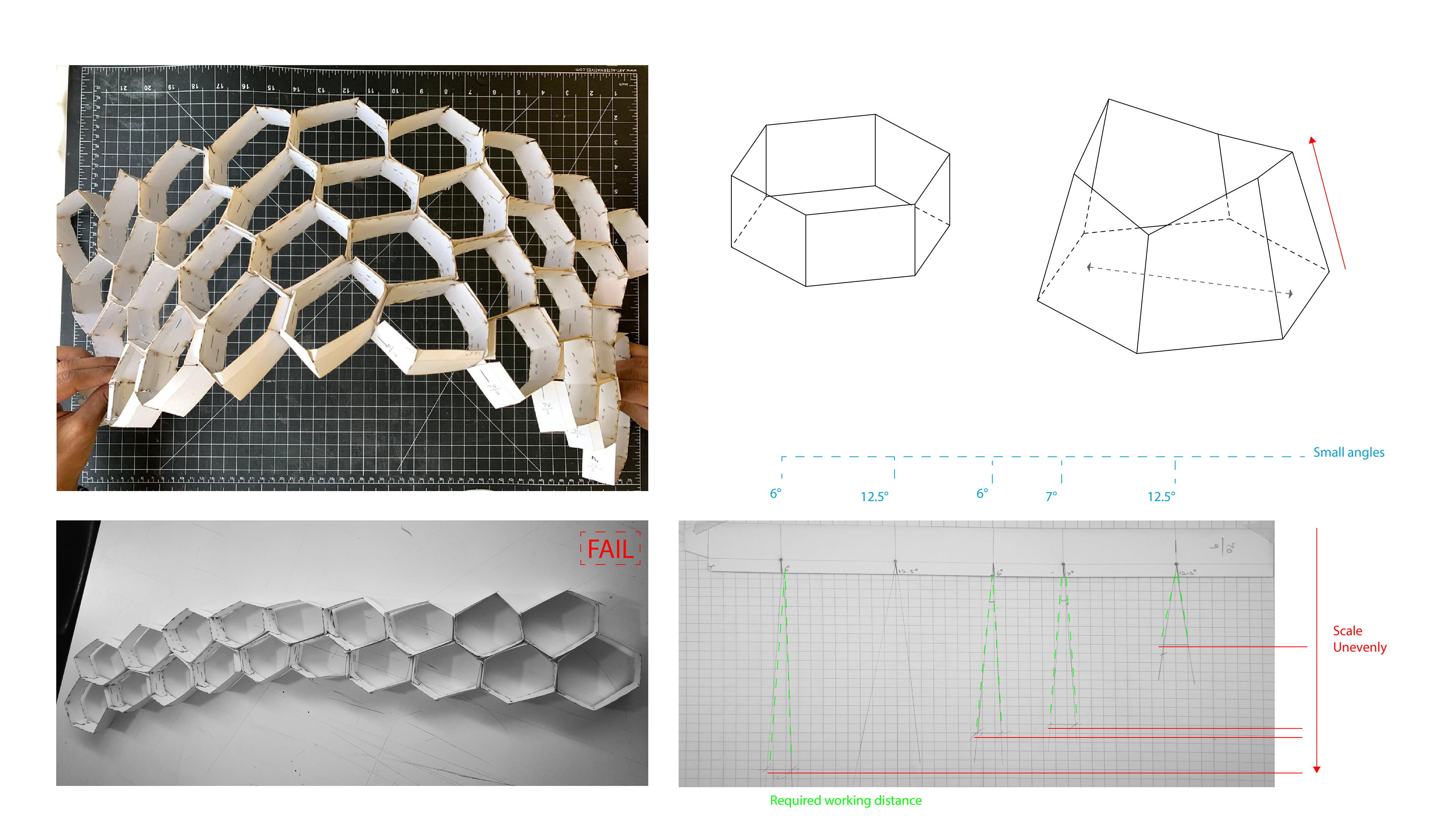

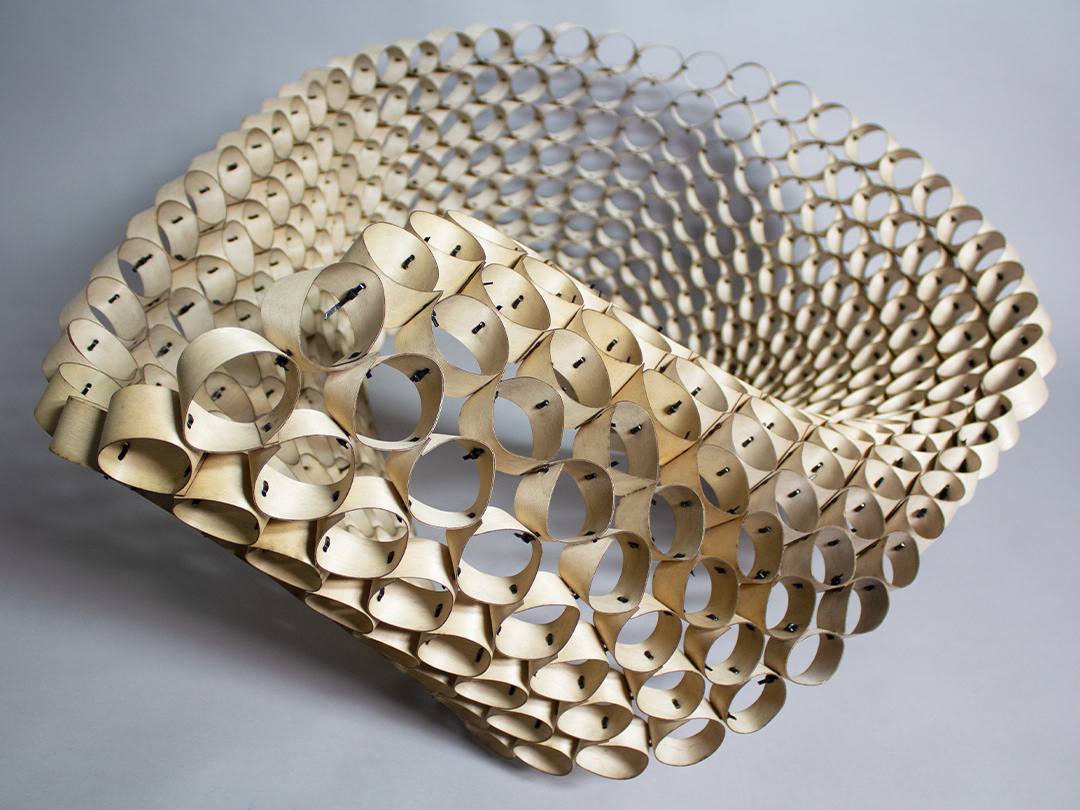

The project was divided into two material phases; paper and thin plywood, which guided our research. The first phase focused on generating a minimal surface that was populated with geometry to be fabricated using paper. Multiple iterations were generated, and the final production of the paper model was created by using a nip and tuck joint to create a quadrant that was the local component for the global form.

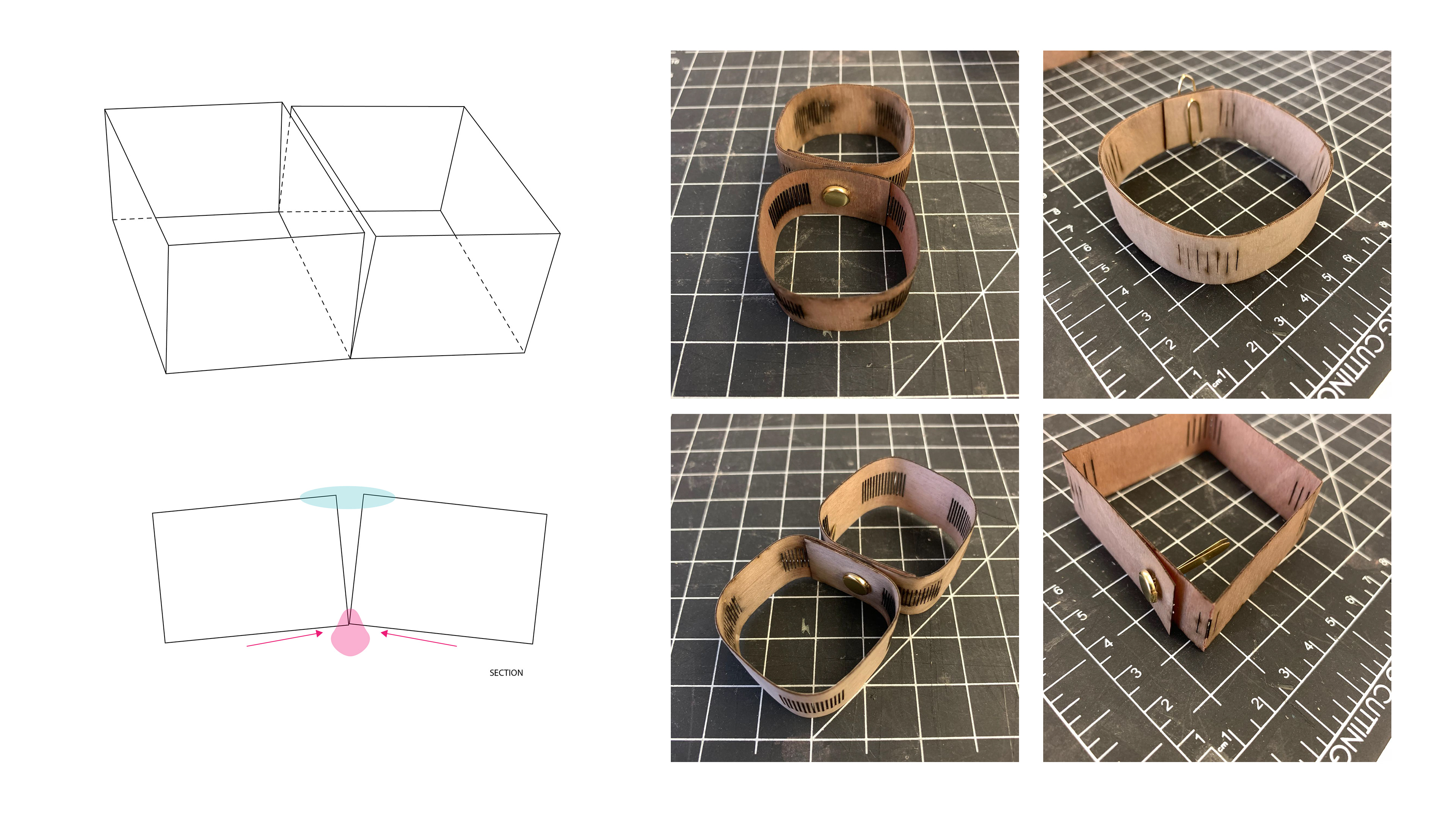

The second phase concentrated on creating the form generated out of phase 1 with thin plywood. In order to understand the material properties of plywood we conducted multiple tests. Through testing we concluded that the best way to manipulate plywood was by soaking it in water to make it malleable and make it easier to fold into our desired shape.

Throughout the different stages we realised that fabricated geometry differs vastly from the digital models. Although we tested multiple geometries, angles and techniques and recalibrated our digital model to match the knowledge gained from these tests, our final plywood model differed drastically from our digital model and a completely new form emerged.